Boom Supersonic extends agreement with Stratasys

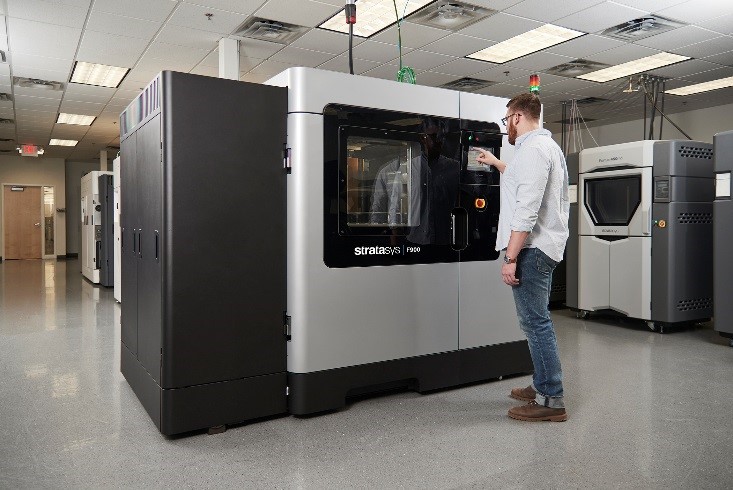

Stratasys F900 3D Printer and Aircraft Interiors Solution (AIS) provide a faster, more streamlined approach to qualify additively manufactured parts for aircraft installation

Stratasys announced it has signed a seven-year agreement extension with Colorado-based Boom Supersonic, a company in the process of building a record-breaking supersonic airliner expected to fly at twice the speed of sound.

Boom Supersonic is utilizing the Stratasys® F900® 3D Printer with the Aircraft Interiors Solution (AIS) package to create hundreds of 3D printed parts for XB-1, the company’s supersonic demonstrator aircraft. According to Stratasys, the package is designed to help improve mechanical properties and enables repeatable development of aircraft production parts.

Mike Jagemann, Head of XB-1 Production at Boom, commented in a statement: “By being able to print critical parts and components on site rather than purchasing them from a supplier, we can create custom parts, increase our speed from engineering to manufacturing, and focus on building the aircraft and fulfilling our vision.

"During the first three years of our partnership, we 3D printed more than 200 parts for tooling, prototypes and test benches using Stratasys’ F370 and Fortus 450mc 3D printers, and have saved hundreds of hours of work time, enabling rapid iteration of design cycles. Stratasys’ standing as a global leader in 3D printed aerospace applications made them an ideal partner for Boom, and we’re excited to extend this partnership long-term.”

“The team at Boom is doing something that’s never been achieved – successful mainstream supersonic airline travel. But development of aircraft that can safely and efficiently travel at Mach 2.2 requires a new approach to manufacturing processes,” said Rich Garrity, President Americas at Stratasys. “Working together, our teams have put the technology to work for efficient, reliable and repeatable prototypes, tooling and jigs and fixtures. Now, we’re ready to go further – for strong, durable, lightweight production-grade aircraft parts.”