Retrofits on the rise, says ABC International

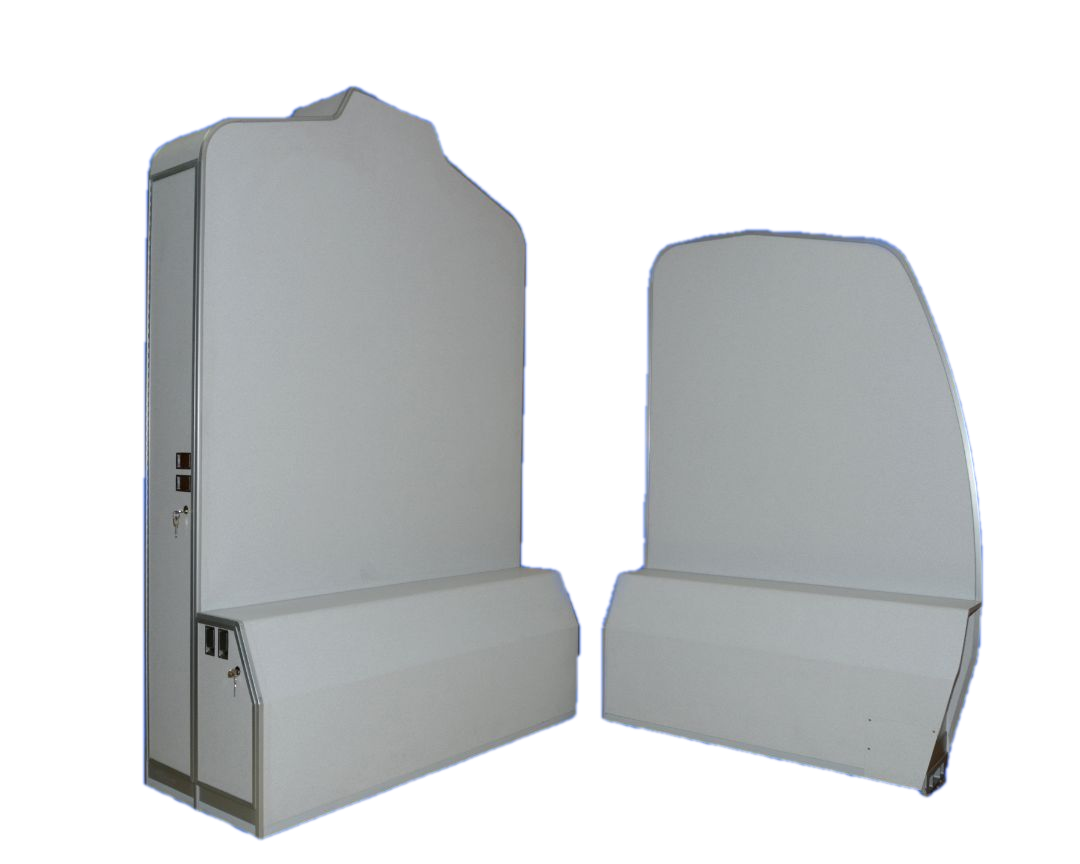

An example of cabin monuments by ABC International

According to cabin branding specialist ABC International, while in recent years airlines focused on maximizing passenger capacity in the cabin, the company is now seeing a larger interest around the word "comfort."

Nowadays, the company says, passengers are demanding quality onboard service with no possibility of losing connection to the outside world, even during flight. The WiFi access on many of today's flights has also given airlines the chance to let passengers promote their brand in-person. This is a great advantage, ABC notes, as long as it is well-managed.

Comfort, it continues, is no longer strictly linked to a nice seating pitch or a delicious meal. It is a package of tangible and intangible elements that need to be combined perfectly together, in order to create an unforgettable experience.

The result is a continuous demand for improvements that has brought huge progress in the design and manufacturing of cabin interiors-related items, according to the company.

ABC International plays its role in this scenario, supporting airlines, MROs and leasing companies with tailored full-package solutions for cabin branding and interior modifications, managed within its EASA privileges that are, above all, easy to implement in order to reduce A/C maintenance ground time.

As the company notes, considering that aircraft OEMs are investing a lot in new technologies with the goal of maximizing passengers’ comfort and at the same time improving fuel efficiency, ABC says it airlines need to standardize their current fleet by implementing “state-of-the-art” solutions.

This is leading to an increase in retrofit project numbers, and ABC International is jumping into this need with lightweight cabin interior kits, such as partitions, class dividers, stowage boxes, soft furnishing Items (for example, carpet, curtain and seat covers) and interior placard sets.

Thanks to its engineering and certification expertise, ABC international says working with it means airlines are given the opportunity to refurbish its cabin interiors with a cost-effective approach while keeping an “Italian” design detail-driven line.

This approach came to life in the latest project that ABC International completed with Turkish carrier Pegasus Airlines. After its successful collaboration with Small Planet Airlines and Meridiana (recently renamed Air Italy) for a A320 partition and 767 fixed class divider, ABC International collaborated with Pegasus, a Sabiha Gökçen-based low-cost airline, for the launch of a new stowage box within its product portfolio. It will be showcased during the Aircraft Interiors Expo in Hamburg April 2 to 4 in hall B6, stand number 6A79.

Pegasus Airlines considered removing coffee makers within its galley compartments, replacing them with boxes in order to optimize space for emergency equipment, and relocating them from overhead bins. ABC International was selected to undertake the project because of its capability to design, certify and release new a emergency equipment layout, thanks to its EASA part 21J approval.

New stowage boxes are made with aeronautical lightweight honeycomb, entirely manufactured in Italy and delivered to customers with EASA Form One, thanks to the DO-PO agreement ABC holds with one of its partners.

ABC International says this latest project opens the door to a new way of thinking by offering airlines new, fast implementation and space-saving solutions, and taking into consideration ABC International's willingness and ability to support small amount requirements as well.

The company says that aircraft cabin interiors may seem too old to renovate until you deal with its team or, as it calls them, "the high-quality and competitive supplier for your next cabin revamping!"

A look at Pegasus Airline's stowage boxes by ABC International